Calving can be a stressful period fraught with danger but simple improvements every dairy and beef farm can make to their existing setup can minimise risk to the operator and the animal.

Whether it is investing in a restraining yoke and gate for assisted calvings or creating dedicated washing facilities with access to hot water, there are changes to suit all systems and budgets.

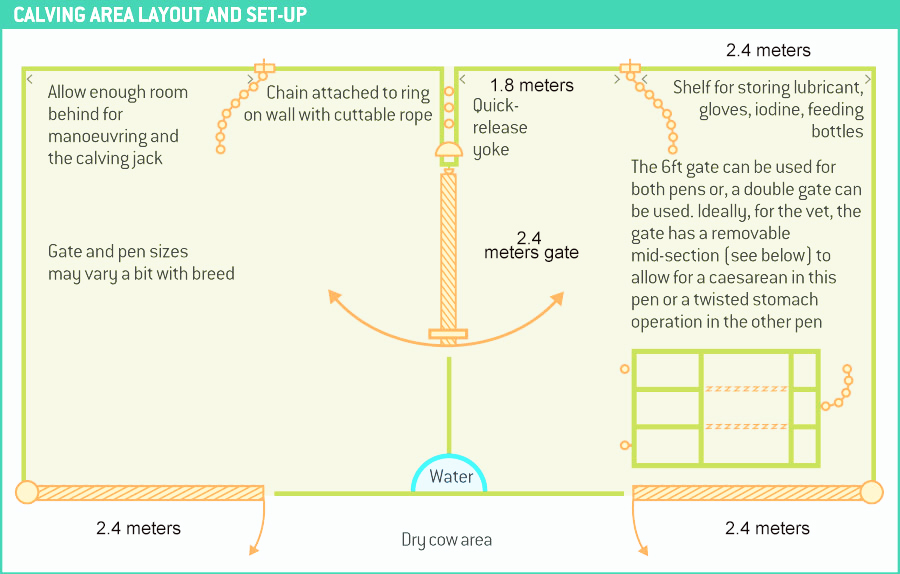

Calving gate and yolk

A headlock and gate are useful for restraining a cow and are particularly valuable when a herdsman is working alone.

There are crushes designed specifically for this job and are ideal for handling lively suckler cows.

His design, pictured below, can be modified to accommodate any size of cow.

A short gate/longer chain combination prevents the cow moving too far forward. If the cow is safely in the yoke the gate may not be needed unless the cow is a bit wild.

- The chain length can be altered, depending on the size of the cow or heifer. A chain attached to a ring on the wall with thick baler twine or similar can be cut if the cow ‘sits’ on the chain as she goes down.

- Mr Davies’ sketch (above) shows how one gate and yoke can cover two calving pens. The handy thing about this design from a vet’s point of view is that surgery can be carried out on either side, for instance, a left flank caesarian or right-side displaced abomasum. This would need an adapted gate with removable middle bars and it is worth chatting with a vet to make sure the gap is in the right place for the size of cows.

- Ensure there is plenty of room behind the chain for the longest calving jack.

- Often a shed has concrete blocks at a height of about 5ft and this is a good height for keeping lubricant gel to hand.At Synergy Farm Health, one farmer client has created a swinging gates/yoke combination to make calving cows easier, pictured below.

Dedicated calving pens

- Pens should ideally be located close to the milking parlour to allow cows to be easily milked after calving.

- The pen must, however, have sufficient privacy to allow the cow to calve in a stress-free environment.

- Using a layer of sand underneath straw, at a depth of 4-6in, provides a good footing and prevents slipping. Sand will help to keep the bacteria load down and the straw can be removed weekly. The sand can then be topped up and covered with straw again.

- Mr. Staak advocates either a “just-in-time” calving method, where cows are moved into the calving pen just as the calf’s feet start to show, or using a large dry cow area for calving cows before moving them to a fresh pen with 12-24 hours.

- In the first approach, the cow is moved to the freshly calved group within 12-24 hours of calving. This approach reduces the impact of being separated from the herd and restricts a decrease in dry matter intake (DMI). Minimal damage is caused to the cow if they are only separated from the herd for a short period.

- If cows are calved in a large, dry cow area, it is best to only add animals to the pen once a week to reduce conflict and to reduce the risk of a drop in DMI.

- Using a layer of sand underneath straw, at a depth of 4-6in, provides a good footing and prevents slipping. Sand will help to keep the bacteria load down and the straw can be removed weekly. The sand can then be topped up and covered with straw again.

- The pen must, however, have sufficient privacy to allow the cow to calve in a stress-free environment.

- It is very important to maintain a stress-free calving environment with minimal movements of cows around calving time. Cows should be moved into the dry cow pen a minimum of 14 days pre-calving to give them time to adjust and help maintain a good DMI.

- The amount of space required for each cow in the close-up dry cow pen is usually linked to yield. A cow producing 8,000 litres needed 8sq m while one yielding 10,000 litres requires 10sq m.

Lighting

Good lighting is an important part of a calving facility, the calving area needs to be well lit.

Check lights before calving – clean covers – and have replacement bulbs on hand.

Good lighting is also essential in the event that a caesarean needs to be performed.

Check calving supplies

Check the availability of basic calving equipment. A good supply of long-armed disposable plastic gloves, obstetrical lubricant, iodine, clean and soft calving ropes, esophageal feeders and calf feeding bottles are essential.

Make sure the calf puller is clean and in good working order.

Remote control cameras

Farmers can monitor and control their herd from anywhere using any web-enabled device by opting for remote access, or mobile security solutions.

One of the more popular benefits of a modern surveillance system is the ability to monitor footage remotely with a mobile app. There’s a wide array of apps that allow a user to log into your system from anywhere with just a touch of your smartphone.

Also, you don’t have to be limited to monitoring only one farm camera remotely. If your farm requires multiple cameras in separate locations, you’re in luck as you can monitor multiple cameras feeds from across multiple locations. This is a popular feature for farmers who need to monitor multiple sheds.